Seeking a sustainable and defensible competitive advantage has become the concern of every manager who is alert to the realities of the marketplace. Logistic and supply chain management plays a key role of an organization both in terms of revenue as well as cost management. Logistic and supply chain management could leads to the source of competitive advantage is found firstly in the ability of the organization to differentiate itself, in the eyes of the customer, from its competition, and secondly by operating at a lower cost and hence at greater profit. This competitive advantage is being lead by marinating the superiority over competitors in terms of customer preference. Markets like Indian and china where markets are fragmented and yet to be explored proper and efficient logistic and supply chain management plays a pivotal role.

Successful companies either have a cost advantage or they have a value advantage, or even better a combination of the two. Customers in all industries are seeking greater responsiveness and reliability from suppliers; they are looking for reduced lead times, just-in-time delivery and value-added services that enable them to do a better job of serving their customers. Value chain or Supply chain activities can be categorized into two types –primary activities (inbound logistics, operations, outbound logistics, marketing and sales, and service) and support activities (infrastructure, human resource management, technology development and procurement). After the recession of 2008 the logistic supply chain management has taken a radical change. In order to keep the profitability numbers in tight range more focus has been deployed on efficient supply management both in term of inbound and outbound segment.

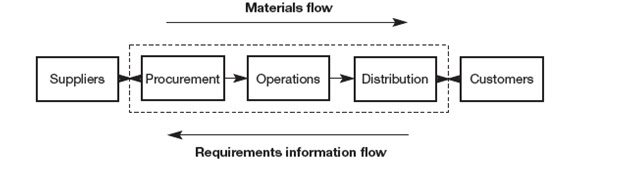

Efficient flow of information and timely supply is the key to success process in emerging markets for supply chain management. In the last decade we have seen the introduction of flexible manufacturing systems (FMS), of new approaches to inventory based on materials requirements planning (MRP) and just-in-time (JIT) methods and, perhaps most important of all, a sustained emphasis on total quality management (TQM). In the last decade we have witnessed that cost of purchased materials and supplies a significant part of total costs in most organizations, but there is a major opportunity for leveraging the capabilities and competencies of suppliers through closer integration of the buyers’ and suppliers’ logistics processes. Supply chain management is an integral part of business process. The power in the distribution channel continues to shift from supplier to buyer, there is also a trend for customers to reduce their supplier base. In other words they want to do business with fewer suppliers and often on a longer-term basis. While I have been discussing about product innovation now it’s the time of process innovation also going to be included in the growth of an long term business. In simple terms it is: Competitive advantage = Product excellence × Process excellence

Product life cycles are becoming short with the rapid increase of innovation. Shortening of life cycles creates substantial problems for logistics and supply chain management. Few of the problems which would be discussed later on in the next series are shorter lead times. Lead times are traditionally defined as the elapsed period from receipt of customer order to delivery. The real lead time is the time taken from the drawing board, through procurement, manufacture and assembly to the end market. This is the concept of strategic lead time and the management of this time span is the key to success in managing logistics operations. Managing the following segments are critical challenges for the logistic and supply chain management 1) shorter lead time and efficient supply.2) Demand driven supply strategy rather than forecast driven.3) Reliability of supply of stocks 4). Partnership sourcing is getting developed.

Online business and shopping business has taken a radical change hence the demand of efficient logistic and supply chain management comes into play. With the current economic situation of the global economy uncertainty is more which has resulted less working capital to be blocked for stocks. Companies are looking for efficient ways through which less stock of products can be made so as to free up the capital requirements. One of the main reasons why any company carries safety stock is because of uncertainty. But the reliability factors still rules the market and hence companies are entering into agreements or partnerships include improved quality, innovation sharing, reduced costs and integrated scheduling of production and deliveries. Underlying all of this is the idea that buyer/supplier relationships should be based upon partnership. Lead time supply has come down where products and services need to be supplied with efficient and prompt communication model. From the suppliers’ point of view, such partnerships can prove formidable barriers to entry for competitors. The more that processes are linked between the supplier and the customer the more the mutual dependencies Increase and hence the more difficult it is for competitors to break in. It is another process of barrier to competition to grow which would help the suppliers to hold a long term relations.

Demand driven supply process is being focused replacing the traditional forecast driven supply methods since after 2008 recession there is more turbulent economic conditions. In order to improve the supply chain methods companies are entering into partnership sourcing model too. These types of model leads to less working capital requirements and linking the same with demand driven rather forecast based hence efficient cost management and working capital financing is being developed.

4 Comments:

I really appreciate information shared above. It’s of great help. If someone want to learn Online (Virtual) instructor lead live training in supply chain management, kindly contact us http://www.maxmunus.com/contact

MaxMunus Offer World Class Virtual Instructor led training on supply chain management. We have industry expert trainer. We provide Training Material and Software Support. MaxMunus has successfully conducted 100000+ trainings in India, USA, UK, Australlia, Switzerland, Qatar, Saudi Arabia, Bangladesh, Bahrain and UAE etc.

For Demo Contact us:

Name : Arunkumar U

Email : arun@maxmunus.com

Skype id: training_maxmunus

Contact No.-+91-9738507310

Company Website –http://www.maxmunus.com

Appreciate !!

Thank you for sharing this good information about SCM. This info will help in my Distance PGDM Logistics and Supply Chain Management.

Thanks for sharing

Thanks for sharing it's a fantastic blog and besides this college/ institute you can also check out MITSKILLS so if you are working professionally this MITSKILLS will be a great help. I am also pursuing a Project Management Professional Prep Course

In order to prepare you for the workforce and provide you with the most up-to-date and pertinent information and skills possible, MIT Skills and PMI are pleased to provide you with our special project management professional certification.

Post a Comment