After the debacle of 2008 the demand of efficiency and defects reduction is on the heights ladder. The debacle of 2008 has taught us to use metrics to measure performance which the world failed to do prior to 2008. While in search of new concepts and thoughts married with new ethical values we forget the ones which are already present matching the same instincts. When I was doing my research on one of the aspects I came across one of very strong and well reputed metrics called Six Sigma. Six Sigma needs no introduction since everyone know the preliminary aspects of its. But I was surprised to find that six sigma is understood less and implemented more in engineering segment rather having an application in every industry comprising of small and big. In this article I will present break up parts of implementation of six sigma for building brands-shifting away from the traditional thought of using it as an statistical tool.

Six Sigma is a data driven process where data accuracy and data collection process is a very important. If ones initial hypothesis is wrong then the whole calculation can go for a wide fluctuation. The data has to be well accurate from the various segments – from manufacturing to transactional and from product to service. If the data is wrong then metrics and measurement both will take a hit. Some of my learned friends might acclaim that Six Sigma is a statistical process of elimination of defects and hence improving productivity. In my research I find that six sigma is beyond statistical calculation and it has a greater role to improve efficiency. Six sigma was designed to control the errors within a system and creating brand value for an organization/its products and even employees.

Six sigma helps to build brand provide if it’s being witnessed beyond as a statistical tool. The Six Sigma DMADV process (define, measure, analyze, design, verify) is an improvement system used to develop new processes or products at Six Sigma quality levels. The word quality is the backbone which creates brand through six sigma process.

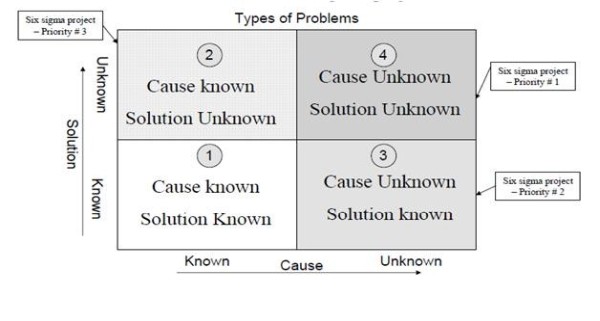

Definition of the problem is the vital pivot point while designing the road map for six sigma. In my research I find that the problem needs to divided into course and solution followed with known and un-know. A matrix is the best suited to understand and efficiently the problem which will form the initial hypothesis.

Once the matrix is well developed behind the mind the initial hypothesis will be a magical solution. We often find that while deriving the definition of problems we get known problems whereas know solutions but they are not linked hence the problems persists and continues. It’s not always prudent to find the unknown questions and answers. Finding the known can be of great help to resolve the unknown solutions and problems too.

For an efficient brand building a proper process needs to develop aligning it with the measurement metrics so that deviation in any place can be identified before the brands is on the verge of collapse.

For an existing product of whom the life cycle suddenly plummet and is on the verge of getting out from the market six sigma definition process can be of great survival for the organization as well as for the product. One must keep in mind that certain changes in an existing product can be of great innovation. Moreover for bringing a new product and getting success from that product is a huge debatable game where as existing product ramification can be of great proposition. The above matrix can be of helpful in improving the quality of a product followed with creating new brand to an existing product.

In my next article I will come up with the measurement part of Six sigma.

1 Comments:

Great article is shared by you! Foam Sealants

Post a Comment